Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

JLY630/6+12+18+24 Planetary Stranding machine

The JLY630/6+12+18+24 Planetary Stranding Machine is purpose-built for stranding control cables, power cables, and XLPE cables with conductors up to 61 wires and cross-sections between 1.5mm² and 6mm². Designed for small and medium-sized cable manufacturers, this machine combines advanced performance, user-friendly operation, and high production efficiency with reliable anti-twist technology.

Product Features

Precision Ground Axis Linkage for Stable Pitch Control

The machine uses a ground axis linkage system to ensure highly accurate and consistent pitch during the stranding process, even at high speeds.

Star-Shaped Gear Twisting Structure for Anti-Twist Performance

Its advanced star-shaped gear cage provides full cable twisting and anti-twist capability, ensuring tight and uniform cable construction.

Cradle-Style Twisting Body for Enhanced Rigidity

The cradle structure enhances the overall rigidity of the machine, supporting high-speed rotation and delivering greater stability and operational lifespan.

Mechanical Friction Pay-Off Tension Control

Each wire pay-off station features adjustable mechanical friction tension, enabling operators to fine-tune wire tension for optimal consistency and cable quality.

Integrated Safety and Lubrication Systems

Equipped with centrifugal break protection, vertical protective covers for each strand, and a separate motor-driven gear pump for lubrication—ensuring safe, smooth, and durable operation.

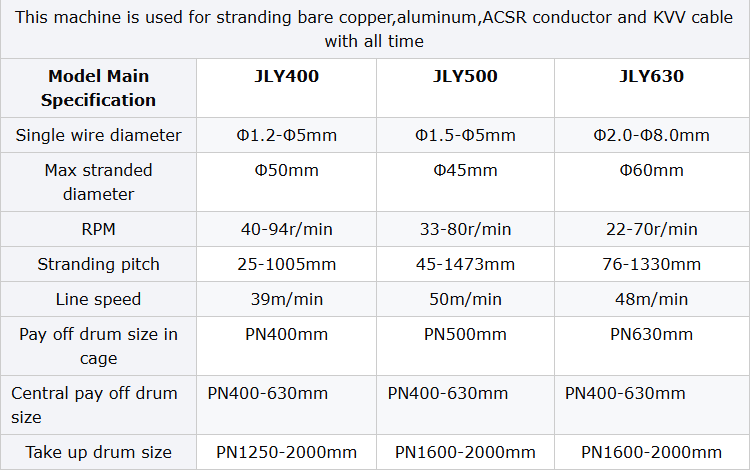

Technical Specifications

Product Advantages

Ideal for Small to Mid-Sized Cable Plants

Designed with practicality and ease of maintenance in mind, this machine meets the operational needs of growing manufacturers.

High Output with Minimal Downtime

Rigid structural design and efficient pitch control contribute to stable, high-speed operation and increased production throughput.

Consistent Quality Across All Wire Strands

Uniform tension control and anti-twist technology ensure balanced and high-quality stranding across all wire sizes.

Low Maintenance, Long-Term Performance

The independent lubrication system minimizes wear on moving components and extends the overall service life of the equipment.

Enhanced Operational Safety

Protective covers and centrifugal braking mechanisms help reduce operational risks, ensuring a safer working environment.

Order Information

- Lead Time: 30-180 days

- Payment Methods: T/T, L/C

- Minimum Order Quantity: 1 unit

- Customization: Available

- OEM & ODM: Supported

- After-sales Service: 24/7 online support, on-site visits possible

- Warranty: 1 year

- Workshop Facilities: Specialized production, welding, and assembly workshops

- Quality Control: Experienced QC engineers (15+ years)

- Logistics: Sea freight, plastic film packaging, wooden boxes at extra cost